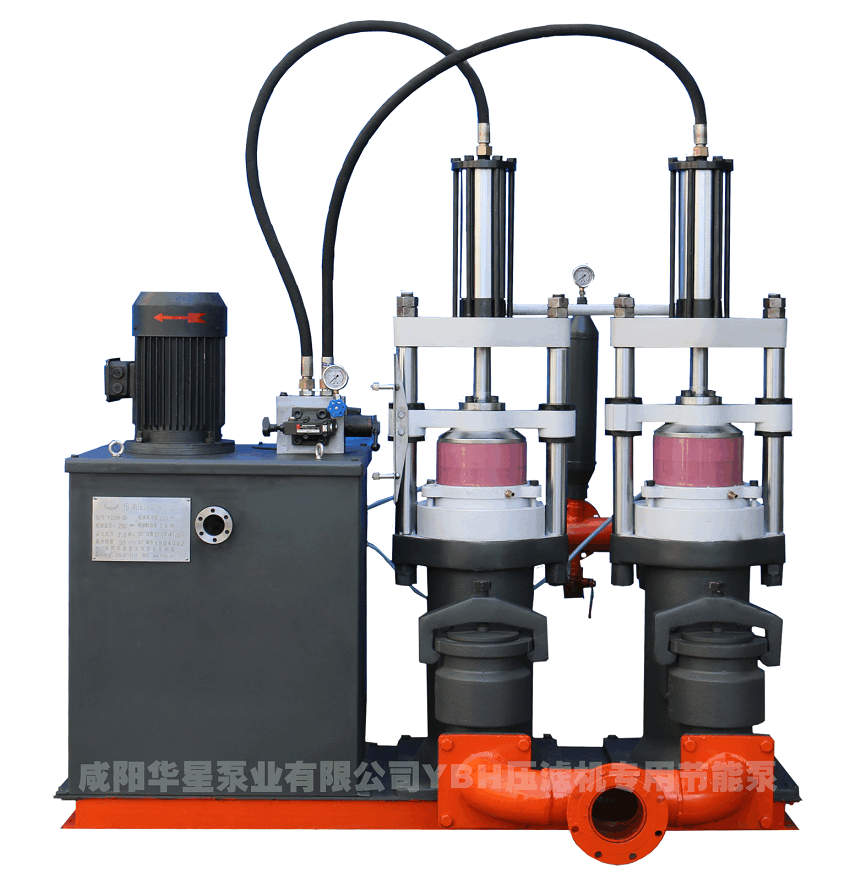

YBH filter press dedicated energy-saving pump

YBH filter press dedicated energy-saving pump

Xianyang Huaxing Pump Industry Co., Ltd

Flow rate: adjustable from 0-160m³/h

Pressure: 0-4 Mpa adjustable

Control mode: manual control/automatic control

Email:18220065811@163.com

Introduction to YBH Filter Press Special Energy saving Pump:

YBH pump is a pressure sensitive variable pump designed specifically for feeding filter presses. It is mainly suitable for the sewage treatment industry when feeding filter presses with a filtration time exceeding 30 minutes. The pump is adjustable constant pressure, automatic variable type.

To understand the performance of YBH type energy-saving pump for filter press, first understand the filtration characteristics of the filter press:

1. Feeding stage: At the beginning of feeding, the filter chamber of the filter press is empty and needs to be quickly filled with material. (YBH pump high flow feed quickly fills the filter press) .

2. Pressure boosting filtration stage: When the pressure inside the filter press is filled with material and the pressure starts to rise, the filter press quickly

discharges water. At this time, the filter press still needs a large flow of feed. As the feed pressure gradually increases, the filter cake inside the high-pressure filter begins to thicken, and the water output of the filter press begins to decrease. The filtering capacity of the filter press also decreases, and the feed rate decreases accordingly. The output flow of YBH pump automatically decreases from large to small, and the hydraulic system has no overflow, starting energy-saving operation ) .

3. Pressure holding filtration stage: The filtration pressure of the filter press rises to the set pressure of Z high, and the feed pressure needs to be maintained at a constant pressure for filtration. The filtration capacity of the filter press further decreases until the filtration is completed. The YBH pump flow rate decreased to z and began to maintain constant pressure feeding, causing a small amount of overflow in the hydraulic system) .

When the pump starts to feed the filter press and perform low-pressure filtration, the high flow rate remains constant. As the pressure of the material in the filter press cavity increases, the filtering capacity of the filter press begins to decrease. When the set value is reached, the hydraulic system controls the YBH pump to reduce its operating speed and output flow rate. The filtering ability of the filter press gradually decreases, the feed pressure gradually increases, and the feed flow rate of the pump automatically decreases. The minimum flow rate is 20% of the rated flow rate, and the pump output flow pressure curve is basically consistent with the optimal filtering curve of the filter press. The entire process is therefore energy-efficient, saving over 60% more energy than ordinary pumps.

|

YB series ceramic plunger pump parameters |

|||||||

|

model |

Rated current m ³ /H |

Pressure Range MPA |

Rated pressure MPA |

stroke MM |

Equipped with motor KW |

External dimensions Length * Width * Height( M ) |

Inlet/outlet flange PN16 |

|

YB85-2.8 |

2.8 |

0-2.5 |

2 |

220 |

4 |

1.29*1.05*1.5 |

DN50/DN40 |

|

YB140-10 |

10 |

0-2.5 |

2 |

250 |

5.5/7.5 |

1.6*1.2*1.6 |

DN80/DN65 |

|

YB200-19 |

19 |

0-2.5 |

2 |

250 |

7.5/11 |

1.7*1.3*1.9 |

DN100/DN80 |

|

YB250-30 |

30 |

0-2 |

1.8 |

250 |

11/15 |

1.94*1.6*2.2 |

DN125/DN100 |

|

YB300-40 |

40 |

0-2 |

1.8 |

250 |

15/18.5 |

2.1*1.8*2.2 |

DN125/DN125 |

|

YB300J-60 |

60 |

0-1.5 |

1.2 |

350 |

18.5/22 |

2.1*1.8*2.32 |

DN150/DN150 |

|

YB300J-60 |

60 |

0-2.0 |

1.8 |

350 |

22 |

2.1*1.8*2.32 |

DN150/DN150 |

|

YB400-80 |

80 |

0-1.8 |

1.6 |

350 |

22/30 |

2.48*2.5*2.6 |

DN150/DN150 |

|

YB400-100 |

100 |

0-1.5 |

1.2 |

350 |

30/37 |

2.48*2.5*2.6 |

DN150/DN150 |

|

YB400-120 |

120 |

0-1.2 |

1 |

350 |

30/37 |

2.48*2.5*2.6 |

DN150/DN150 |

The above are basic models, and customized products can be made for special needs.

Customized production can fully meet your requirements

CUSTOMIZATION PROCESS

1. Online consultation with customer service to have preliminary communication with you, and arrange for engineers to have detailed one-on-one communication with you

Arrange engineers to create a plan based on your working conditions and provide a quotation

Both parties determine the plan and price, and sign the contract

4. Arrange production and deliver on time

5. Arrange guidance for installation and debugging of equipment

6. Post sales service