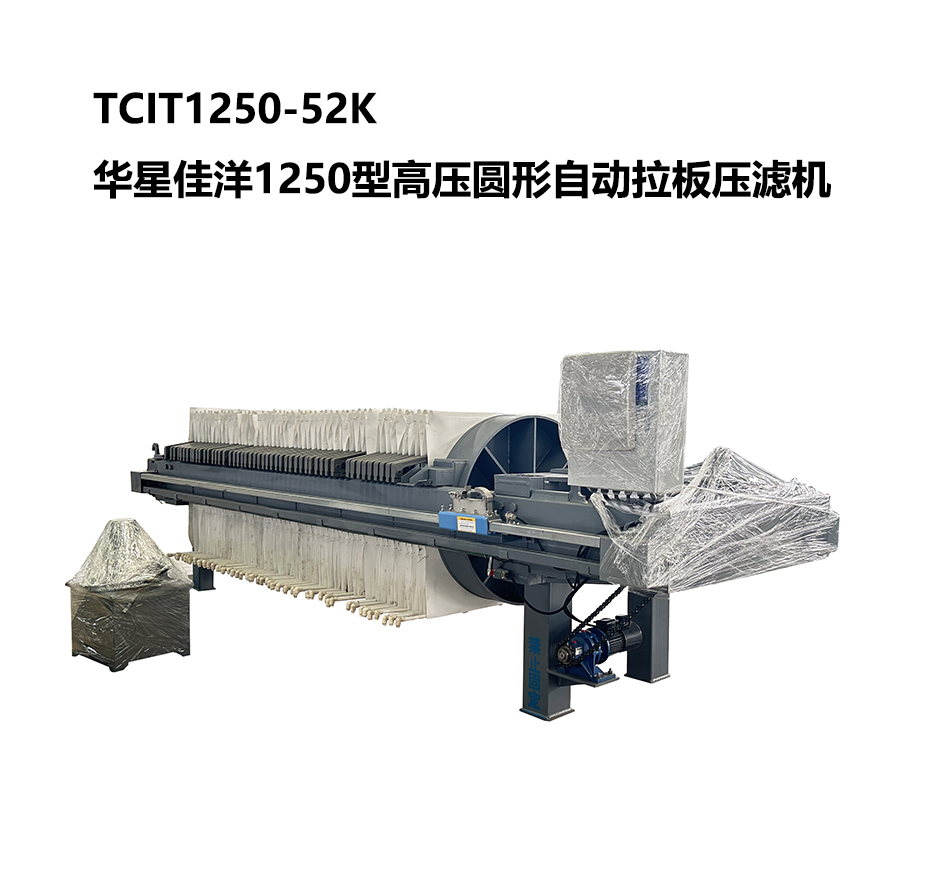

Ultra high pressure automatic hydraulic filter press

This equipment is the main equipment for dewatering slurry in industries such as ceramics, electric ceramics, chemical engineering, light industry, food, pharmaceuticals, and environmental protection. It uses pressure filtration to dehydrate slurry into mud cake. The general pressing pressure is 12-30kg/cm2 (1.3-2Mpa), and the mud temperature is generally 25-35 ℃. Each round of pressing takes 0.5-1.5 hours. After pressing, the moisture content of the mud cake is 18-26, and it is used as aged mud material to enter the vacuum mud mill.

This machine is mainly composed of an oil cylinder base, a fixed plate, a polymer polyethylene plate, a guide rod, an intermediate support, a pressing plate, an oil cylinder, a hydraulic station, etc.

The hydraulic system of this machine is divided into two types: a. manual compression, manual release, and hydraulic self-locking; b. Automatic compression, automatic release, automatic compensation, hydraulic self-locking. The entire equipment is installed on a reinforced concrete foundation with drainage channels, which is easy to install and operate. Users can choose according to their own situation.

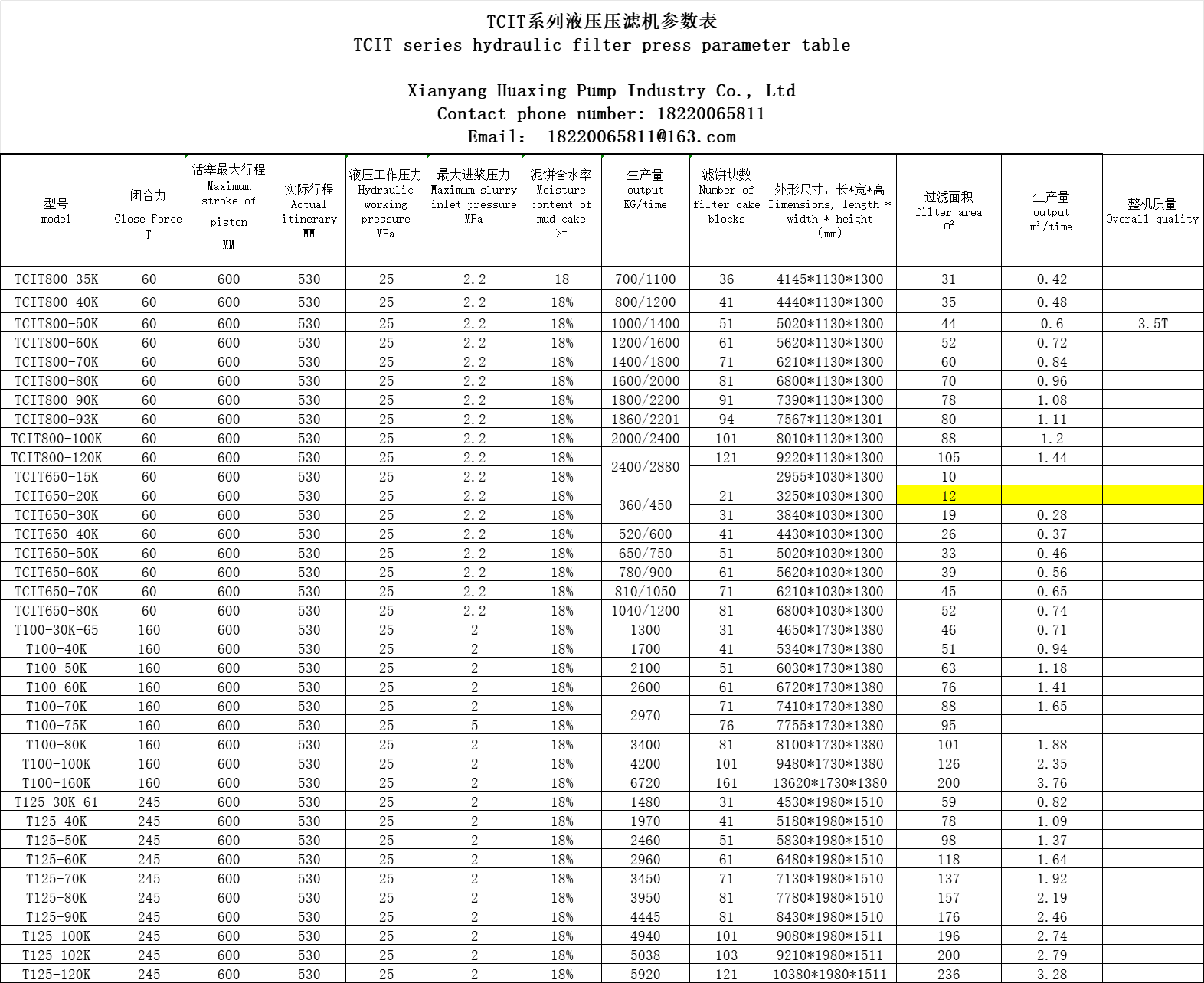

Parameters of ultra-high pressure automatic hydraulic filter press

click to enlarge:http://www.hxhb9.com/uploadfile/202508/7750d5fd38489ad.png

Parameters of ultra-high pressure automatic hydraulic filter presshttp://www.hxhb9.com/uploadfile/202508/7750d5fd38489ad.png