YNC hydraulic viscous material conveying pump

It is mainly used for solid-liquid separation and transportation of filter cakes and mud cakes

Used for conveying filter cakes, mud cakes, filter residues, mud residues, soil residues, etc. from plate and frame filter presses, horizontal screw centrifuges, belt filter presses, stack screw machines, vibrating screens, rotary screw machines, etc., after dehydration, to dryers, loading, and transfer.

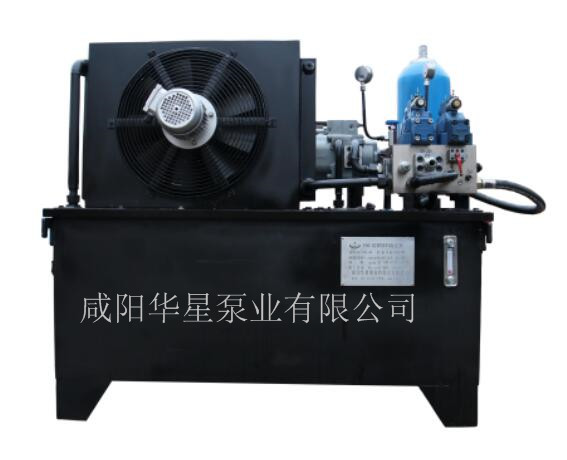

The S-valve piston pump consists of a dual-shaft helical pre-compression machine, a piston pump with an S-tube, a hydraulic system, and an electronic control system.

It is primarily used for transporting: dehydrated municipal sludge, coal slime, dry tailings, kitchen waste, mine filling tailings and coal slag, hazardous waste, viscous oil sludge, etc. It can also be used for high-pressure spray combustion of hazardous waste slurry.

S-valve pump

Flow range: (10-300m³/h)

Pressure range: (2-10MPa)

The cone valve piston pump consists of a dual-shaft screw pre-compressor, a cone valve piston pump, a hydraulic system, and an electronic control system.

It is primarily used for conveying: dehydrated municipal sludge, oil sludge, coal sludge, filter cake, mud cake, dry tailings, kitchen waste, mine filling tailings and coal slag, hazardous waste, viscous oil, high-concentration slurry, etc. It can also be used for high-pressure spray combustion of hazardous waste slurry.

Cone valve pump

Flow range: (10-300m³/h)

Pressure range: (2-20MPa)

Customized production can fully meet your requirements

CUSTOMIZATION PROCESS

1. Our online customer service will conduct a preliminary communication with you and arrange for an engineer to have a detailed one-on-one communication with you

2. Arrange for engineers to develop a plan based on your working conditions and provide a quotation

3. Both parties confirm the plan and price, and sign the contract

4. Arrange production and deliver on time

5. Arrange and guide the installation and commissioning of equipment

6 Post-sale service