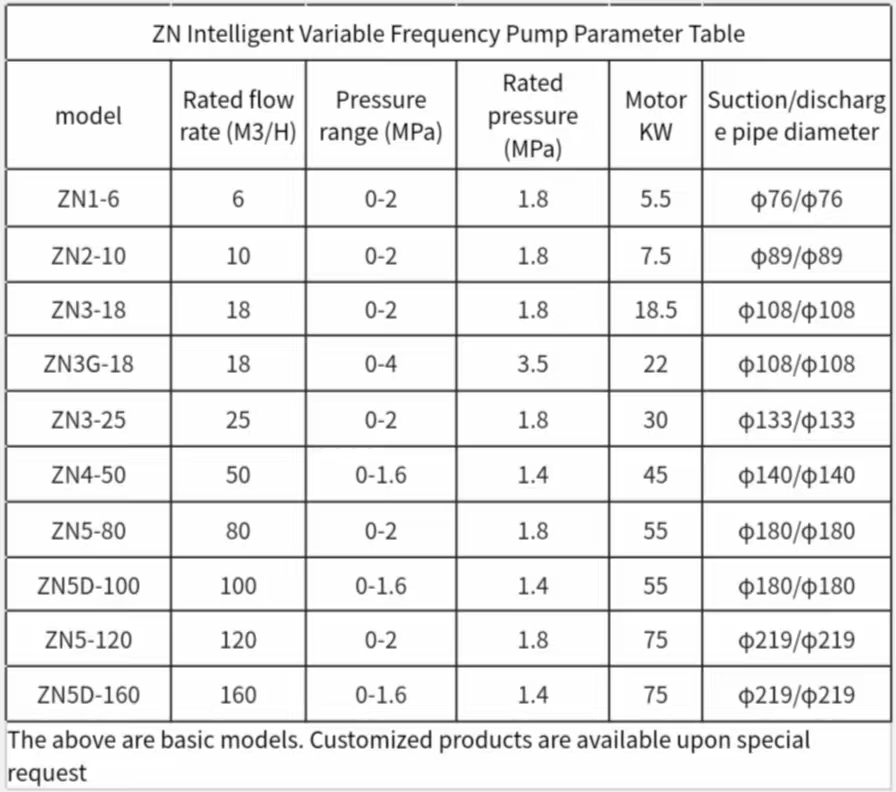

ZN Intelligent Variable Frequency Pump

Advantages of hydraulic plunger mud pump

1. Wear resistance: The plunger is made of alumina ceramic fired and finely ground, with a hardness of HLC8.5 or higher and a surface roughness of 0.4um. There is no shear motion between the plunger and the conveyed material Suitable for conveying materials containing sand and solid particles.

2. Strong self-priming ability: plunger type vacuum pumping method, self-priming ability of 4-8 meters (material density determines suction range change)

3. Adjustable constant pressure automatic variable: The working pressure of the plunger mud pump can be adjusted within the range of 0-20 kilograms. The adjusted pressure will not change due to changes in the output flow rate of the pump, and will maintain the set pressure unchanged. Even if the outlet of the running pump is closed, the pressure will not change. (The change cannot exceed the large flow rate of the pump, and the flow rate can be zero)

4. High pressure: The regular model has a high pressure of 20 kilograms When the pressure is ≥ 5 kg and the flow rate is the same, the motor power of the plunger slurry pump is 1 to 2 models lower than other types of pumps.

5. Easy to operate: Pressure adjustment only requires tightening or loosening the pressure regulating valve. After adjusting the pressure, lock it and there is no need to adjust it again in the future.

6. Low operating cost: The vulnerable parts of the pump are the valve plate and plunger seal Replace ceramic mud every 3-6 months and municipal sludge every 6-12 months

7. Long service life: The service life is at least 15 years.

8. Customized production: Based on the actual working conditions of each user, flexibly configure and customize products that meet their production needs.

Introduction to ZN Intelligent Variable Frequency Pump

Performance characteristics:

1. The structure is novel, the operation is simple, the flow rate is large, the pressure is high, the vibration is small, the pressure fluctuation is small, and the energy-saving effect is significant.

2. The plunger seal adopts new materials and structures to extend its service life, reduce replacement frequency, and eliminate water lubrication. Sealing replacement is simple and fast, and the annual maintenance cost is only one-fifth of that of screw pumps.

3. The touch screen input parameters are simple and clear, with real-time fault alarms and display of fault points for easy maintenance. Real time uploading of pump operating parameters through external ports enables remote monitoring and operation. It can also be connected to other devices to achieve automated control.

Product Introduction:

The Zn series intelligent variable frequency pump is a newly developed hydraulic filter press feed pump by our company. After three years of research and development, the pump has three components. Integrating intelligence and versatility, it is currently a professional filter press feed pump.

Based on the filtering characteristics of the processed materials and the model of the filter press, the program for the required working curve for filtering can be conveniently written on the display screen. The required pressure, flow rate, and time for a certain stage of filtering can also be written in segments to achieve control over material filtering and achieve optimal filtering effect. The intelligent pump monitors the data during the filtration process and calculates the moisture content of the filter cake inside the filter press internally. When it meets the set requirements, it will automatically stop and give a discharge signal to the filter press for unloading. After unloading, the filter press will press down and the intelligent pump will automatically start feeding, achieving fully automated operation of the filter press.

The main wear-resistant components of ZN intelligent pump are made of alumina ceramic fired and polished to a mirror finish, with a service life of more than 5 years. Intelligent frequency conversion controls the entire filtration process to achieve overflow free operation. The structural design eliminates the need for long flowing lubrication of the plunger pump, greatly improving the working environment, making maintenance simpler and faster, and increasing the efficiency of the filter press.

The product is primarily used for spray drying, dewatering of feed material in filter presses, and high-pressure transportation of slurry.

For feeding into the filter press, based on the filtration characteristics of the processed material, the required filtration curve can be easily entered through the display screen to achieve optimal filtration results. The intelligent pump monitors data during the filtration process and calculates the moisture content of the filter cake inside the filter press through internal calculations. Once the set requirements are met, it will automatically shut down and send a discharge signal to the filter press for unloading. After unloading, the filter press tightens, and the intelligent pump automatically starts feeding, enabling the filter press to operate fully automatically. The ZN intelligent pump improves work efficiency, saves filtration time, and reduces energy consumption.

When used in a spray drying tower, after startup, the user only needs to set the working pressure on the display screen. During pump operation, the program will automatically adjust the motor speed to achieve overflow-free operation under the condition of constant set pressure, thus achieving optimal conveying efficiency and reducing energy consumption. Compared to the original working method of plunger pumps relying on overflow valves for pressure regulation, it saves more than 30% energy. When operating with variable frequency, it reduces oil temperature and simultaneously reduces wear on the oil pump and hydraulic components, extending the service life of hydraulic components.

Customized production can best meet your requirements

CUSTOMIZATION PROCESS

1. Our online customer service will have an initial communication with you and arrange for an engineer to have a detailed one-on-one communication with you

2. Arrange for engineers to develop a plan based on your working conditions and provide a quotation

3. Both parties confirm the plan and price, and sign the contract

4. Arrange production and deliver on time

5. Arrange for guidance on installing and debugging equipment

6 Post-sale service

上一篇:YB high-pressure ceramic plunger mud pump

下一篇:YB stainless steel acid resistant ceramic plunger mud pump